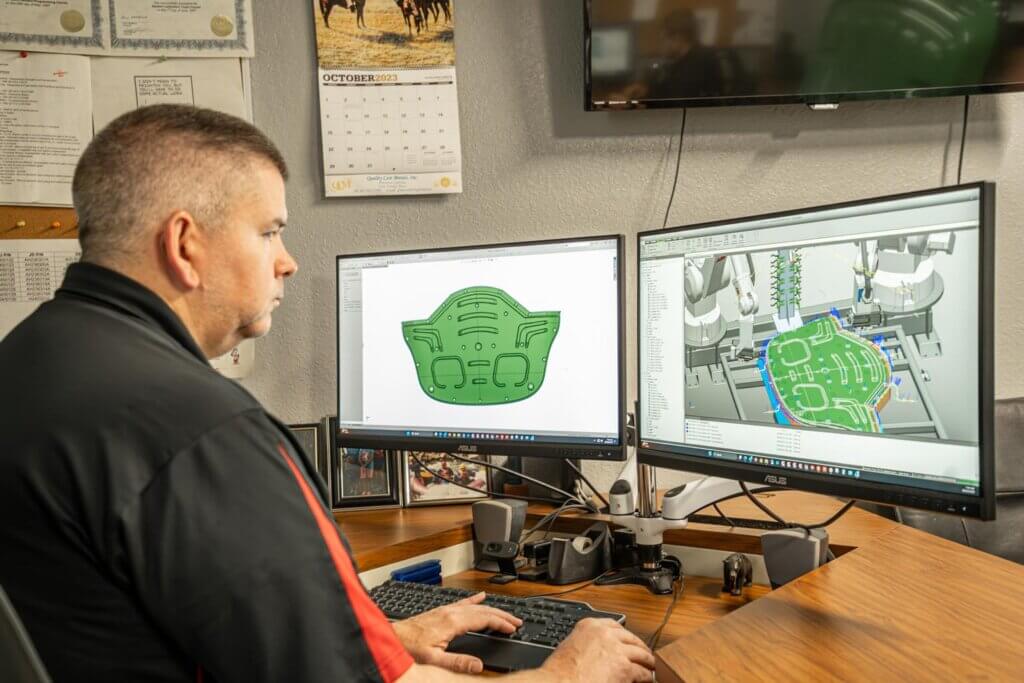

Tooling design is the foundation of manufacturing. The engineers in our in-house design/tooling team are proficient in a variety of design software, including Solidworks, MasterCAM, and Robot Studio. They use these tools to take your ideas, goals, and design criteria from concept to production.

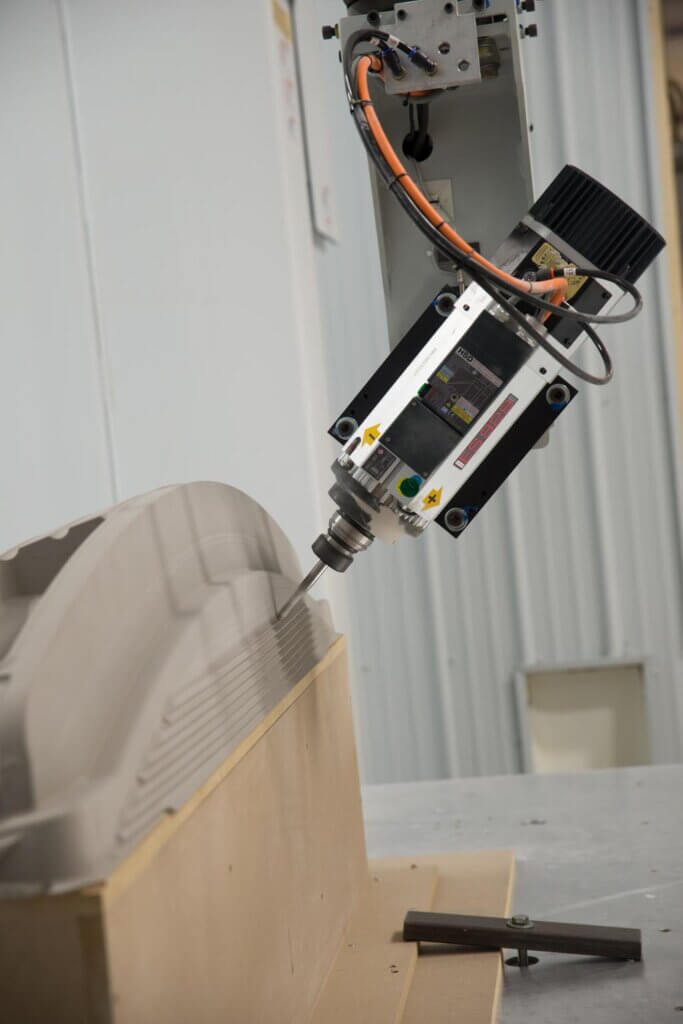

Our designers and tool makers produce thermoform, composite, and urethane molds in-house.

Many times, a customer has the exact specs and won’t settle for any variances. Other customers might have a general purpose in mind and require design services and samples from us. Our in-house design team will work with your team to help you generate the CAD design needed and then design the tooling to bring your ideas to life.

As mentioned above, our engineers have extensive design software expertise in Solidworks, MasterCAM, and Robot Studio. We use Solidworks for designing and reviewing CAD models and drawings in any IGES, Pro/E, Inventor, or STEP file. We use MasterCAM to generate programs for trimming and machining on our CNCs. We use Robot Studio to offline program our ABB and Fanuc robots.

Our molds have temperature control to make sure consistent parts are formed. This increases efficiency and ensures all parts shrink constantly.

Parts are trimmed robotically on our CNC routers.

Our experienced staff will help you find a solution that will work best for each individual application. We take the time to make sure we completely understand your needs. We do this so we can provide you with the best materials and processes. Our comprehensive due diligence ensures that we will make you the best possible design and tooling for your application.

Plastics Unlimited started as a thermoforming company over a quarter of a century ago. We’ve evolved into a composites and urethane molding company, as well, and we continue to learn and grow as a leading plastics manufacturer every day.

If you want an industry-leading in-house design/tooling team to help you with your products, contact us today.